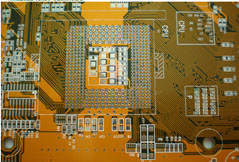

Printed Circuit Boards (PCBs) are the boards that are used as the base material in most electronics. It is used both as a physical support piece and as the wiring area for surface-mounted & socketed components. They care commonly made of fiberglass, composite epoxy, and other composite material. Using different conductive pathways or signal traces etched from copper sheets, a PCB mechanically support and electronically connect electronic components. PCBs have evolved over the years and today it is used in virtually all the commercial electronic devices, and allows fully automated assembly processes. A PCB populated with electronic components is called printed circuit board assembly (PCA), printed circuit board assembly or PCB assembly.

Where are the PCBs commonly used?

The Multilayer printed circuit board are mostly associated with computers and they can be found in many other devices like TVs, Radios, Digital cameras, and Cell Phones. Also, different types of PCBs are used in medical devices, industrial machinery, lighting, and automotive industry.

There are several types of PCB boards with its own specification, types and usage. They are –

Single-layer PCBs

Double-layer PCBs

Multi-layer PCBs

Rigid PCBs

Flexible PCBs

Rigid-Flex PCBs

High-frequency PCBs

Aluminum-backed PCBs

The structure of multilayer laminates is far more complex than double-sided PCBs. Multi-layer PCBs consists of a series of 3 or more double-layered PCBs. These boards are secured using a specialized glue and it ensures that excess heat doesn’t melt any of the components. They come in different sizes and the largest one was built 50 layers thick. The complex designs are suitable for a broad range of complicated electrical tasks. Applications in which multilayer PCBs can be beneficial are file servers, data storage, GPS technology, satellite system, weather analysis, and medical equipment.

It is stacked-up or built-up and has an organized layered structure, which is usually arranged symmetrically around its justify. The cross-section has mainly 3 components namely copper foils, cores and prepregs. All parameters of multilayer PCBcomponents are standardized, especially the thickness values.Prepregs are manufactured in the form of single glass fibers that are saturated with partially polymerized epoxy resin. A pressing process is applied during which high pressure and high temperature melt the fibers, which binds the individual stack layers together.The multi-layer PCBs can be manufactured according to the use and need. Customized PCBs are designed and prepared by manufacturing company according to the client needs.